Customer Success in Precision Measurement, 3D Visualization and Data Management

F3 has served more than 800 world-class customers over the last 10 years.

Civil engineers leveraging F3 measurement and data solutions during construction.

Case Study - infrastructure

Client: U.S. Federal Agency

The Project/Task:

- $900M to refurbish existing infrastructure, build new dam.

- Update existing assets, protect Sacramento region for next 200 years.

The Challenge:

- New construction, replicating existing structures while the dam was in operation.

- Unprecedented demand for accuracy of measurements.

- Managing multiple contractors, with overlapping project plans & timelines.

F3 Solution:

- Combination of 3D scanning, laser tracking and conventional surveying methods to capture and position critical assets within project tolerances.

- To assist with design and construction, a 1:50 scale version of the dam (3D printed model) produced with interactive removable parts which engineers and project managers used during daily safety meetings and rehearse complicated operations.

The Data & Results:

- Enhanced cross-contractor communication, operation efficiencies and employee safety increased.

- 800 GPM preconstruction water leakage, post construction - 75% reduction in waste with estimated 315M gallons saved over 12 months.

- Engineering News-Record Magazine award winner – Best Project.

3D print of refinery assets, developed from 3D laser scans & models, used to rehearse extraction plan.

CASE STUDY - OIL & GAS

Client: Fortune 500 Refinery

The Project/Task:

- Replace the 26’ long manifold with four 2’ diameter flanges used to offload the crude from the oil tankers to the refinery.

The Challenge:

- 48 hour turnaround given tanker schedules which included taking existing manifolds off line and installing replacements.

- Heavy congestion surrounded the manifold (i.e. hard to reach asset), requiring testing of crane operations prior to removal.

- Anything less than precise measurements would result in total project failure, lost productivity and revenue.

F3 Solution:

- Traditional land surveying methods to establish the project datum in the project area.

- 3D scanning and metrology to accurately capture the manifold, its flanges and all the surrounding industrial congestion.

- Fabrication drawings from the data captured to enable the accurate manufacturing of the new manifold offsite.

- 3D scanning and metrology to verify the new manifold accurately matched the existing manifold on site (still in operation at this point).

- Accurate 3D print of the entire area surrounding the manifold with removable parts for plant operators to rehearse the proposed extraction plan.

The Data & Results:

- Project completed within 48 hours without incident.

- Need to shut down plant operations eliminated, preventing nearly $1M in lost revenue.

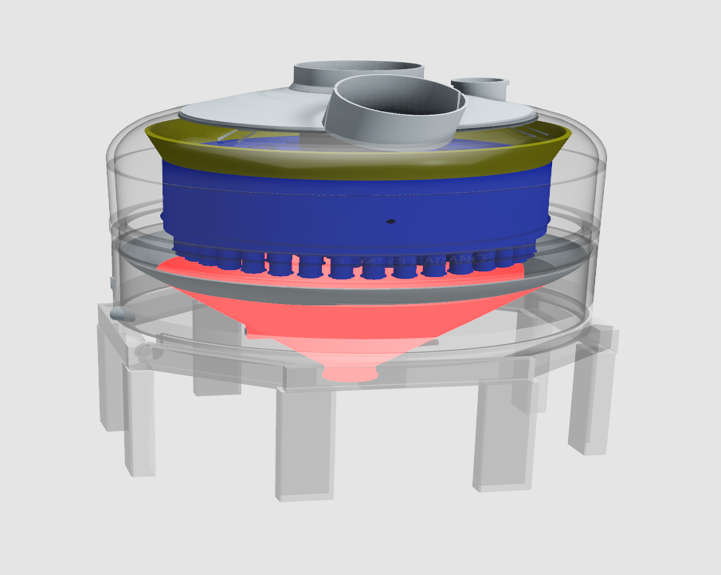

3D CAD model used for design and construction of asset.

Case Study - Energy

Client: Multinational Company

The Project/Task:

- Replace critical components within a third-stage separator with an extremely short shut down window.

The Challenge:

- Replace a component in a refinery that a majority of the product gets filtered through while minimize operational downtime.

- No documentation available that would allow for offsite construction to occur prior to shut down.

F3 Solution:

- Engineering grade fabrication drawings based on 3D scan and conventional surveys that enabled asset construction offsite.

- Data on demand and virtual models used for designing, planning and construction.

- 1:12 scale 3D print of asset used to save costs and reduce project timeline.

The Data & Results:

- Shortened project plan by two days, netting $1M savings.